Table of Contents

Defect Prevention Plan (DPP)

Defect Prevention Plan The purpose of Defect Prevention is to identify the Root cause of defects and prevent them from recurring.This involves analyzing defects that were encountered in the past and taking specific actions to prevent the occurrence of those types of defects in the future.

Defect Prevention (DP) is a strategy applied to the software development life cycle that identifies root causes of defects and prevents them from recurring the uncertain defect in SDLC process.

Objective of defect prevention

The objective of defect prevention is to identify the defects and take corrective action to ensure they are not repeated over subsequent iterative cycles. Defect prevention can be implemented by preparing an action plan to minimize or eliminate defects, generating defect metrics, defining corrective action and producing an analysis of the root causes of the defects.

Defect prevention (DP) activities are intended to improve quality and improve productivity.

Defect Prevention is a Proces whose purpose is to

- Identify the common causes of defects and

- Change the relevant process(es) to prevent that type of defect from recurring (SEI)

Steps to accomplish Defect Prevention

Defect prevention can be accomplished by accomplishing the following steps:

- Calculate defect data with periodic reviews using test logs from the execution phase: this data should be used to segregate and classify defects by root causes. This produces defect metrics highlighting the most prolific problem areas.

- Identify improvement strategies.

- Escalate issues to senior management or customer where necessary.

- Draw up an action plan to address outstanding defects and improve development process. This should be reviewed regularly for effectiveness and modified should it prove to be ineffective.

- Undertake periodic peer reviews to verify that the action plans are being adhered to.

- Produce regular reports on defects by age. If the defect age for a particular defect is high and the severity is sufficient to cause concern, focussed action needs to be taken to resolve it.

- Classify defects into categories such as: critical defects, functional defects, and cosmetic defects.

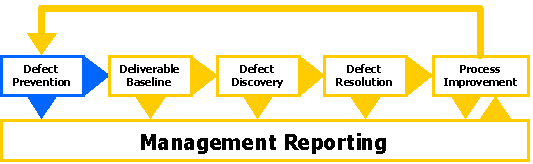

Defect Management Process

Without a doubt, the best approach to defects is to eliminate them altogether. While that would be ideal, it is virtually impossible given current technology. In the meantime, developers need strategies to find defects quickly and minimize their impact. Identifying and implementing the best defect prevention techniques (which is a large part of identifying the best software development processes) should be a high priority activity in any defect management program.

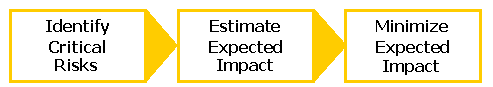

Defect prevention should begin with an assessment of the critical risks associated with the system. Getting the critical risks defined allows people to know the types of defects that are most likely to occur and the ones that can have the greatest system impact. Strategies can then be developed to prevent them. The major steps for defect prevention are as follows:

Defect Prevention Process

Identify Critical Risks — Identify the critical risks facing the project or system. These are the types of defects that could jeopardize the successful construction, delivery and/or operation of the system.

Estimate Expected Impact — For each critical risk, make an assessment of the financial impact if the risk becomes a problem.

Minimize Expected Impact — Once the most important risks are identified try to eliminate each risk. For risks that cannot be eliminated, reduce the probability that the risk will become a problem and the financial impact should that happen.